Supply chain management and logistics are commonly viewed as the backbone of every business. It can be the differentiating factor that leads to the success of a business or, unfortunately, the catalyst that leads to their downfall. In today’s increasingly interconnected global economy, businesses simply can’t thrive and outperform competitors without a strong supply chain management model in place.

Supply chain management is often a daunting challenge for many small and medium-sized businesses (SMBs) simply due to a lack of expertise, time, and capital to effectively manage the supply chain. Businesses that understand what supply chain management is and the associated benefits can partner with the right contract manufacturer to create an optimized and tailored end-to-end supply chain strategy that encompasses logistics, transportation, and warehousing that will successfully scale as production needs fluctuate.

Top Three Reasons to Partner With a Supply Chain Service Provider

- Proactively Identify Potential Production Problems

- Dynamically Optimize Price

- Reduce Waste and Incorrectly-Filled Orders

What is Supply Chain Management?

In order to fully understand supply chain management, we first need to understand what a supply chain is. A supply chain is a network composed of a company, its suppliers, and customers that focus on the core activities and transactions within a business required to convert raw materials or components into a finished salable product or service.

The supply chain network includes personnel, equipment, technology, information, and transportation modes. The departments involved in the company’s supply chain network commonly include sales, sourcing, procurement, production, logistics, and customer service.

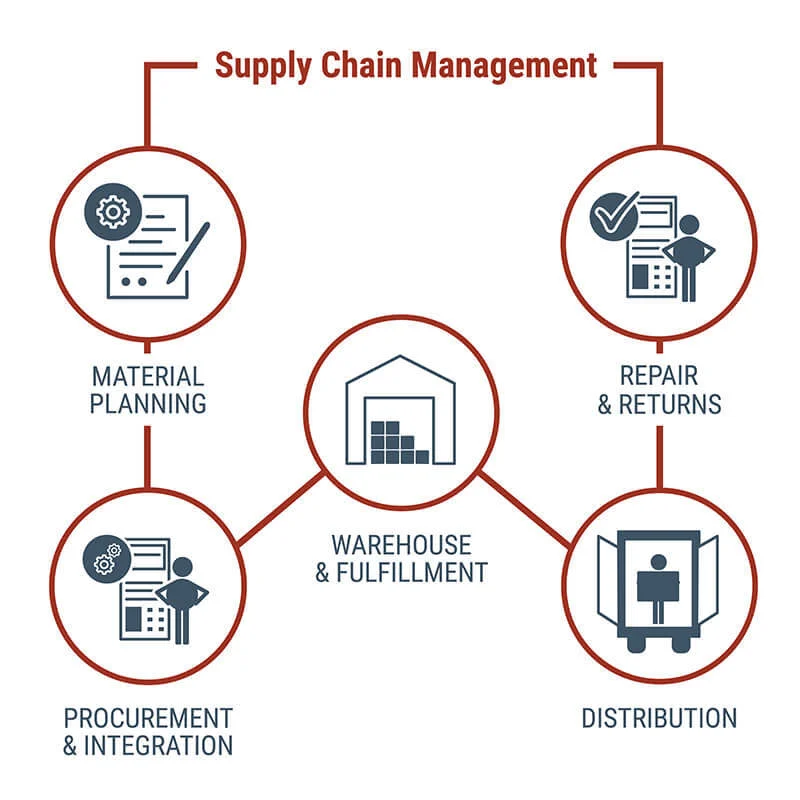

Supply chain management, however, is defined as the coordination, management, and strategy of the entire production flow of a good or service – from initial planning and sourcing through final product delivery – to supply the highest quality products and services to stakeholders and customers. To state it simply, supply chain management is the sequence of activities that assists a commodity or service to move from manufacturing to the marketplace. A company creates a network of suppliers, referred to as links in the chain, which move the product from the suppliers of raw materials to those organizations that deal directly with users.

Why Supply Chain Management is Important

When a company’s supply chain is unified under strategic forward-thinking management, supply chain management becomes a driving force for a competitive advantage. It provides increased efficiency, reduced production friction, and decreased costs throughout the production process to deliver a product or service that exceeds customer expectations.

Effective supply chain management systems minimize cost, waste, and time in the production cycle especially when they are managed by a contract manufacturer that is certified to ISO 9001:2015 QMS standards and upholds 6-S lean manufacturing principles. To illustrate the importance of partnering with a supply chain service provider, here are three ways an intelligent supply chain management strategy can bolster the efficiency of your supply chain cycle:

- Proactively Identify Potential Production Problems – By leveraging supply chain management software and analytic tools, manufacturers can ensure they always have the necessary inventory to meet customer demand. A tightly monitored supply chain is able to proactively anticipate potential production problems and alleviate them before the buyer is disappointed.

- Dynamically Optimize Price – Does your company experience seasonal demands? Due to the limited shelf life of seasonal products, many companies sell these products at steep discounts or adjust prices dynamically to meet the current demand. Businesses can leverage supply chain management and analytic software to engage in predictive analysis to improve margins.

- Reduce Waste and Incorrectly-Filled Orders – Intelligent supply chain management provides manufacturers with analytical software tools to assist the dynamic allocation of resources based on orders, sales forecast, and delivery of raw materials to reduce unnecessary waste from the production process. Manufacturers can utilize management software to confirm and track product delivery to ensure no orders are incorrectly filled.

Get in touch:

Increase Your Production Efficiency with Adaptable Supply Chain Management

Engaging in supply chain management alone is like sitting down to do a 1000 piece puzzle blindfolded. It’s not conducive to success. However, businesses that take the time to understand their limitations and partner with an experienced contract manufacturer to oversee their supply chain receive a tailored strategy based on their unique production cycle in order to boost efficiency and ensure on-time delivery for high-quality products or services.

Businesses and manufacturers no longer have to worry about being left alone to solve their supply chain puzzle. The right supply chain partner will take off your proverbial blindfold and work lockstep alongside you from start to finish until each piece of the supply chain puzzle is correctly placed.