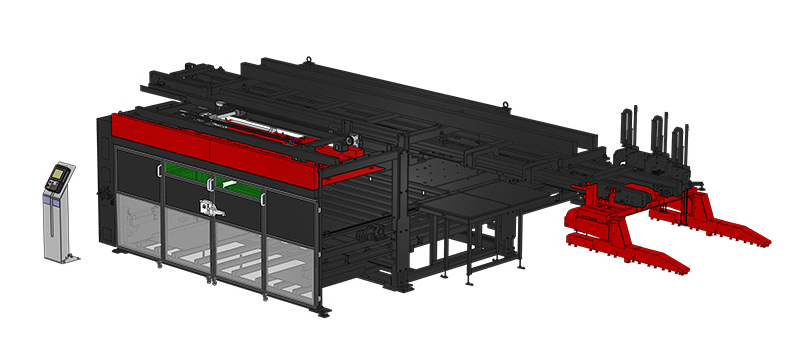

We are thrilled to announce the acquisition of a state of the art punch laser combo machine. In the ever-evolving landscape of sheet metal fabrication, staying ahead of the curve is paramount for success. The EML2515-AJ, a revolutionary punch laser combination machine engineered by Amada to redefine manufacturing efficiency, precision, and versatility.

This machine combines a 33-ton turret punch press with a 3kW fiber optic laser system, allowing for high-speed production of short-run sheet metal parts and provides manufacturers with several benefits over traditional methods.

Let’s explore the advantages of the EML2515-AJ, highlighting its key features and demonstrating how it achieves new heights of productivity.

Technical Specifications & Capabilities

- Motion System: The machine uses a pneumatic sheet clamping system that moves the workpiece in the X and Y-axis for punching operations. During laser cutting, the clamps move the sheet in the X-axis, while the laser cutting head moves in the YL-axis. The system is driven by ball screws and servo motors for precise positioning.

- Punching System: The EML2515-AJ has a 33-ton punching capacity and a maximum punch rate of 500 hits per minute on 1” centers. It features a 55-station “MPT” turret with four built-in tapping stations. The machine also utilizes a power vacuum die system that aids in slug removal and enhances tool life.

- Laser System: The machine features a 3kW Amada AJ3000 fiber laser resonator. This fiber laser system is three times more energy-efficient than comparable CO2 laser systems. The machine also has an automatic focus control for processing various material types and thicknesses.

- Control System: The EML2515-AJ is equipped with an AMNC-4ie control with a 21.5” HD touchscreen interface. The control stores a comprehensive cutting data library for the laser and allows operators to modify cutting parameters as needed. The control also features a built-in video monitoring system (V-Monitor) that records and stores program execution for process monitoring and troubleshooting.

- Safety Features: The EML2515-AJ includes several safety features such as a “Table Cabin” that encloses the workpiece during laser cutting, a non-contact capacitive cutting head system to prevent surface marking, and optional safety mats and light curtain guarding for operator safety.

- Automatic Loading: The machine utilizes the RMP-3015 NTK which is a flexible system composed of a combination machine loader – un-loader and parts remover. It has been worked out to rationalize the raw material and machined parts flow, in order to increase productivity. The rigid tubular welded construction is based on a simple design that provides autonomy and flexibility.

Benefits for Our Customers

- Increased Efficiency and Productivity: The combination of a punch press and laser system allows manufacturers to perform multiple operations in a single setup, reducing part handling and labor costs. The machine’s high-speed punching and laser cutting capabilities, combined with its automated features, further enhance productivity.

- Cost Savings: The EML2515-AJ’s energy-efficient design reduces energy consumption compared to traditional CO2 laser systems. The machine’s servo-electric ram system eliminates the need for oil replacement, reducing maintenance costs and environmental impact. Additionally, the machine’s ability to process a wide range of materials and thicknesses reduces the need for specialized tooling.

- Improved Part Quality: The EML2515-AJ’s advanced motion control and rigid construction ensure high precision and repeatability. The machine’s “Punch and Form” (P&F) feature and “Floating Brush Table” (FBT) allow for complex forming operations with minimal scratching or deformation. The laser system’s high cutting speeds and precise beam control result in clean, accurate cuts with minimal heat-affected zones.

- Flexibility and Versatility: The EML2515-AJ can handle a wide range of materials and thicknesses, making it suitable for various applications. Its large work envelope accommodates both small and large workpieces. Additionally, the machine is compatible with various automation options, allowing manufacturers to tailor the system to their specific production needs.

Overall, the EML2515-AJ offers manufacturers a comprehensive solution for sheet metal fabrication. Its technical specifications, capabilities, and advanced features translate into increased efficiency, cost savings, improved part quality, and enhanced flexibility, enabling businesses to stay competitive in today’s demanding manufacturing landscape.

Click here to see a list of all of our Key Equipment or don’t hesitate to reach out in the form below to see how we can help you with your next project.