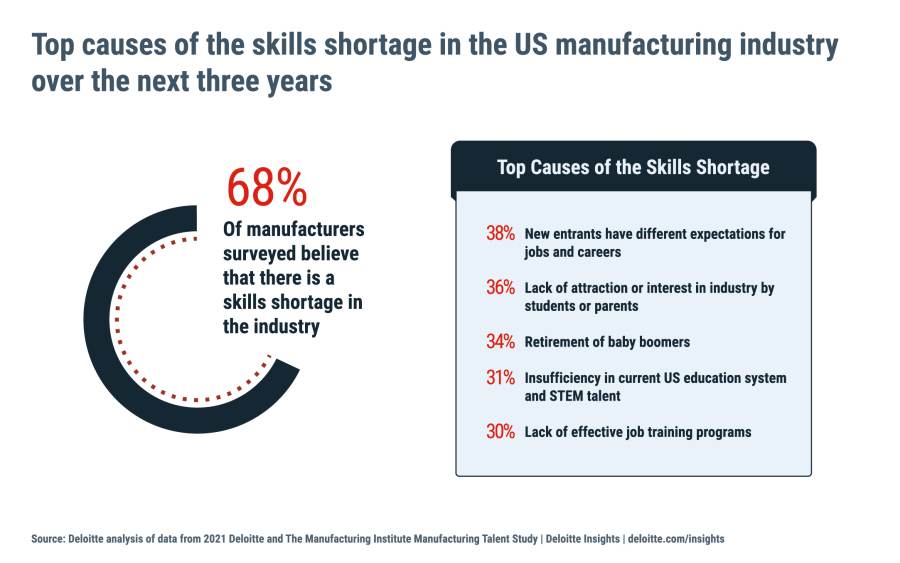

As the number of vacant entry-level manufacturing positions continues to grow, manufacturing and industrial leaders are finding it increasingly difficult to maintain a poker face. By 2030, the manufacturing skill gap is projected to result in a need for 2.1 million skilled manufacturing workers and with 2.6 million baby boomers expected to retire from their manufacturing jobs in the following decade, manufacturing leaders are starting to utter the alarming phrase, “talent shortage.”

However, hiring isn’t as easy as it used to be. According to The Manufacturing Institute, U.S manufacturers believe that manufacturing hiring is now 36% harder than it was in 2018 with 78% of manufacturers stating they project experiencing difficulties in attracting and retaining workers in 2021 and beyond.

Before explaining how contract manufacturing can solve these problems, let’s take a closer look at the multiple factors causing the manufacturing hiring challenges in the first place.

What are the Factors Impacting Hiring in the Manufacturing Industry?

While it may be easier to attribute the current hiring challenges plaguing the manufacturing industry purely to the pandemic, the reality of the situation is more complex. From COVID-19 to demographic implications, here are the confluence of factors negatively impacting Original Equipment Manufacturers’ (OEMs) ability to hire a complete skilled workforce.

Demographic Factors

There are several demographic factors contributing to manufacturing hiring difficulties. Since these factors are all occurring concurrently, their detrimental effects are compounded creating the multiple challenges facing manufacturing companies.

Shrinking populations – According to the recent Census, 16 states saw their population decrease as the United States experienced the slowest national population growth since the Great Depression.

Aging populations – The 65-and-older population grew by 34.2% over the past decade. As baby boomers continue to age, the viable applicant pool for manufacturers to hire from will continue to shrink.

Low unemployment rates prior to the pandemic – Many states were experiencing low unemployment rates even before COVID-19. Low unemployment rates make it increasingly difficult to recruit the right talent to fill open manufacturing roles.

COVID-19 Factors

It will come as no surprise that the pandemic has caused OEMs of all sizes to quickly scramble and try to fill the gaps in their workforce. The manufacturing industry netted a startling loss of 578,000 jobs during the pandemic-challenged year of 2020. OEMs also face an accentuated fluctuation of consumer demand. With decreased demand for some products and increased demand for others, OEMs need to find a way to remain flexible and quickly adjust production volume as needed.

3 Ways Contract Manufacturing Alleviates OEM Employment Difficulties

COVID-19 and other demographic factors have greatly impacted OEMs’ ability to attract and hire new talent. However, manufacturers can leverage partnering with a contract manufacturer to alleviate these pain points and guide them through the current hiring crisis.

Here are three ways contract manufacturing can help OEMs overcome hiring challenges to remain profitable, productive, and competitive.

Provides a Consistent Workforce for Immediate Labor Shortage Relief

Maintaining a capable, motivated, and available workforce continues to remain a key challenge for many manufacturers. Lucky for OEMs, contract manufacturing provides immediate relief in a labor shortage and removes the burden of dealing with an unpredictable workforce.

The value of partnering with a reliable and experienced contract manufacturer lies in their ability to quickly and consistently provide OEMs, regardless of size, the workforce they need to meet the fluctuating demands of their customers. Whether an OEM needs 10 or 1,000 pieces of product assembled, a qualified contract manufacturer will provide a consistent workforce at a cost-effective price to ensure a streamlined assembly.

Reduces Time and Money Spent on Recruitment

Another way contract manufacturers are positioning themselves as a solution to OEM hiring headaches is by providing an avenue to reduce time and money spent on recruiting new talent. Recruitment is a time-consuming process and anything that takes time also has financial impacts. The average U.S. employer spends more than $4,000 to hire a new employee, and it takes approximately 42 days to fill an open position. Onboarding with a contract manufacturer can take as little as 2-3 weeks, saving the company valuable time and money.

OEMs simply cannot afford to wait over a month to fill a skilled position as customer demands continue to fluctuate more rapidly. With the talented and experienced workforce contract manufacturers have on hand, manufacturing companies can forgo over-spending on maintaining or growing a skilled workforce.

Eliminates the Need for Continuous Training and Onboarding

Certain manufacturing industries require specific knowledge and technical expertise to ensure production quality and customer satisfaction. These manufacturing skill gaps are only widening as the manufacturing industry transitions to industry 4.0. Industry 4.0 refers to the trend of digitization in manufacturing and the marrying of advanced manufacturing techniques like automation and data exchange with the Internet of Things (IoT) to improve production, performance, and output.

Hiring someone with the skills, experience, and insight needed may be nearly impossible depending on available resources, timing, and other factors. Contract manufacturers consistently have trained and experienced labor on hand to meet the various technical specifications and quality standards expected from their customers.

Maintain Profitability and Overcome Your Hiring Challenges with Contract Manufacturing Services

Manufacturing hiring challenges is unquestionably an issue that will continue to plague the industry long after the pandemic ceases. But this isn’t your issue to lose sleep over as a manufacturer. Take advantage of qualified contract manufacturers and leverage their fully-trained and experienced workforce to avoid the current manufacturing hiring challenges.