Specialization and niche fulfillment of customer needs in business are critical to success. Who can possibly excel at every aspect of operating a business today? Partnering with MSI empowers visionary and creative owners, leaders and management teams to “focus on what they do best,” and to “do what they like most.”

There are many reasons why manufacturers trust MSI. Here are the top ten:

Top Ten Reasons Why Manufacturers Trust MSI

Stability of Fixed Per-Unit Pricing

Stabilizing labor costs is the common denominator for most businesses. Fixed per-unit pricing effectively flattens out the variable costs of production labor.

Security of a 100% Zero-Defect Guarantee

If MSI fails to meet client-specified standards, the client is credited. Product returns costs due to workmanship are eliminated.

Reduced Overall Per-Unit Costs

Implementing ISO 9001:2015 Standards assure consistently higher quality products, translating into fewer product returns, improved customer satisfaction, increased repeat orders and referrals.

On-Demand Workforce – Over 200 Manufacturing Techs

A capable, trained and available workforce remains a challenge for most manufacturers. In very short order, MSI can adjust, train and deploy skilled technicians to take on nearly any process.

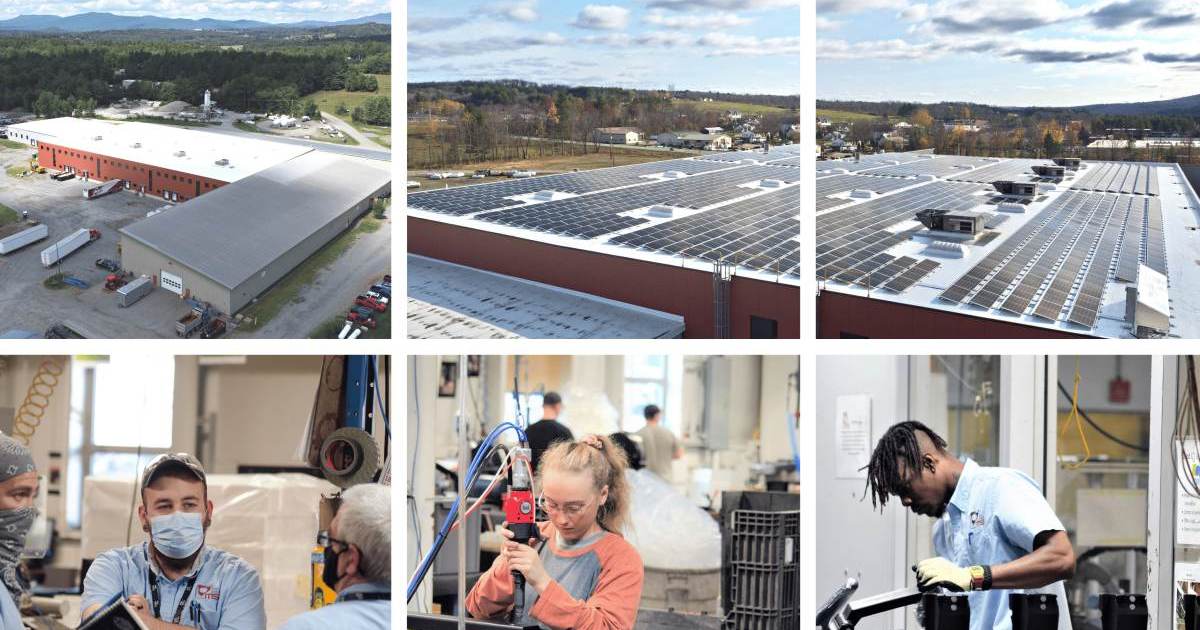

Immediate Space for Production

With nearly 400,000 SF over multiple locations, including a recently constructed 68,000 SF expansion, MSI has an abundance of production space ready to go, eliminating the need for client investment in real estate buying or leasing and/or capital construction financing costs.

Expedited Delivery Schedules – Getting Back on Schedule

All products run into scheduling issues from time to time. When this happens, partnering with MSI scales up production volumes without sacrificing quality or reputation, and without hiring production staff only to offer layoffs when production volume eases.

Empowering Clients to Focus on Core Business Strategies

Focusing on one’s core business is critical to success. By partnering with MSI, clients find increased quality time and improved success in areas such as:

- Long & Short-term Planning & Strategizing

- Analyzing New Business Opportunities

- New Product Development

- Existing Product Improvement

- Sales & Marketing Initiatives

- Improving Customer Satisfaction (Reviews)

- Increasing Repeat and Referral Sales

- Internal Team Building, and more

Flexibly Scaling Up & Down with Client Orders

Most manufacturers strive to achieve a steady, reliable level of production. What happens when a customer doubles their order for next month? Hire people? Train people? Move production lines around to accomodate? Lease more space? Add-on to the building!

Minimize Hiring, Retention & Employee Turnover Costs

In August of 2016 SHRM (Society of Human Resource Managers) published a survey indicating the average cost to hire an employee is $4129 and it takes an average of 42 days to hire. The hiring cost alone generally outweighs the cost of contracting with MSI, with onboarding in as little as 2-3 weeks. If a company must hire ten employees to meet their production schedule, that adds up to over $40,000 just in hiring.

No Interest in Managing a Large Team of Production Workers

Not everyone has the luxury of attracting, training, retaining and adequately compensating highly paid process engineers, production managers and capable leadership professionals. Not all business owners have an interest in taking on this sometimes-daunting task at all. By contracting with MSI for their production and supply chain aspects, a business owner can focus on watching their business grow, by managing sales, marketing and customer satisfaction, leaving the lion’s share of employee chalenges to MSI.