At Manufacturing Solutions Inc. (MSI), we provide advanced metal fabrication and contract manufacturing services trusted by aerospace, defense, and industrial leaders. Now, with the addition of the OMAX 60120 JetMachining® Center, we’ve expanded our precision cutting capabilities to include 5-axis waterjet cutting—enabling tight-tolerance, aerospace-grade results on nearly any material.

Advanced Waterjet Cutting Services Now In-House

MSI’s in-house waterjet cutting system allows for ultra-precise cuts without the heat distortion of traditional methods. It’s the ideal solution for manufacturers demanding tight tolerances, clean edges, and material flexibility across metals, composites, plastics, and more.

Waterjet Cutting Advantages:

- Precise to ±0.001”

- No heat-affected zones (HAZ)

- Compatible with aerospace alloys and sensitive materials

- Eco-friendly and cost-efficient

- Suitable for low- to high-volume production

With our waterjet cutting services integrated into our Vermont facility, we reduce lead times and streamline your supply chain—from raw material to finished product. Our full lineup of advanced in-house equipment supports every stage of precision fabrication—explore it here.

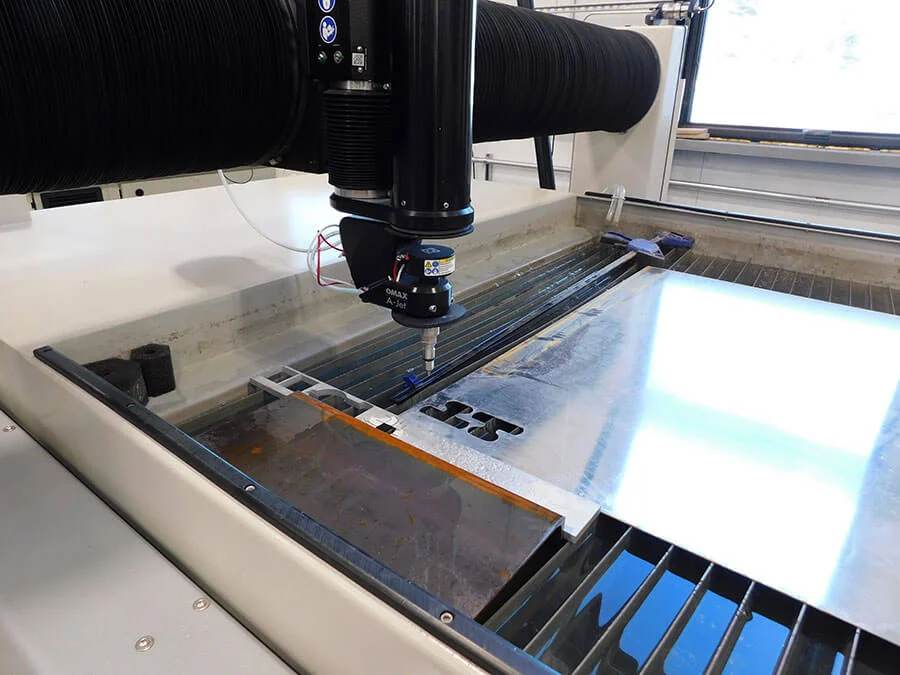

Meet the OMAX 60120 JetMachining® Center

The OMAX 60120 is one of the most advanced waterjet cutting systems available for contract manufacturers. It’s engineered for high-speed, high-accuracy cutting of complex parts from aerospace alloys, industrial metals, and specialty materials.

Top Features:

- Large cutting envelope – ideal for oversized or nested parts

- 5-axis cutting for complex geometries

- EnduroMAX® pump – highest nozzle horsepower in the industry

- IntelliVISOR® system – real-time performance and predictive maintenance

- Scissor-style plumbing for safety and operational reliability

MSI offers all customers a 100% defect-free guarantee on finalized products. The newest custom cutting machine will continue to uphold these standards as maintaining customer satisfaction is paramount.

Contract Manufacturing with Aerospace-Grade Precision

As a contract manufacturing partner, MSI is ISO 9001:2015 certified and ITAR compliant, with experience producing aerospace-grade fabricated parts. Our precision fabrication process includes:

- 5-axis abrasive waterjet cutting

- Laser welding & CNC machining

- Tight-tolerance forming & assembly

- Powder coating, phosphate coating, and more finishing options

- Inspection & CMM quality control

- Integrated warehousing and logistics

Our facility supports both prototype and production-scale jobs with a 100% defect-free guarantee.

Your Fabrication Partner for Aerospace and Beyond

Whether you’re producing parts for aerospace, defense, medical, or industrial equipment, MSI is a partner you can trust to deliver precision, performance, and speed. With our vertically integrated operations and expanding capabilities, we’re built to support your entire production lifecycle.

Let’s Talk About Your Metal Fabrication Project

If you’re sourcing a contract manufacturer with cutting-edge waterjet cutting capabilities, contact MSI today. We’re ready to support your next build with high-precision fabrication and advanced cutting services.