Choosing the right precision cutting method is critical to balancing quality, speed, cost, and material performance in any contract manufacturing project. Whether you’re cutting carbon fiber for aerospace components or high-strength steel for industrial equipment, selecting the best cutting process — waterjet, laser, or static cutting — can make all the difference.

At Manufacturing Solutions Inc. (MSI), we now offer a full suite of advanced cutting technologies including:

- OMAX 60120 JetMachining® Waterjet Center

- Amada EML-2515 AJ Fiber Laser/Punch Combo

- Eastman M9000 Static Cutting Table

In this article, we’ll break down the differences between waterjet and laser cutting, and help you understand when each process is the right fit for your project.

Waterjet Cutting: Maximum Versatility Without Heat

Waterjet cutting uses a high-pressure stream of water mixed with abrasive materials to slice through hard and soft materials. Unlike thermal cutting, waterjet cutting does not generate heat, preserving material properties and eliminating heat-affected zones (HAZ).

Key Advantages of Waterjet Cutting:

- Material Flexibility: Ideal for cutting metals (steel, stainless, aluminum, titanium), composites, stone, glass, plastics, and ceramics.

- No Heat-Affected Zone: Protects materials sensitive to heat distortion — critical for aerospace, medical, and high-precision applications.

- Thickness Capacity: Cuts virtually any material thickness up to 12″, though most jobs are 3″ or less for optimal speed.

- Precision: The OMAX 60120 achieves tolerances of +/- 0.005”, even on intricate geometries.

- Prototyping-Friendly: Minimal setup allows quick turnaround on small production runs or prototypes.

- Surface Finish: Clean edge quality with no secondary processing often required.

When to Use Waterjet Cutting:

- Thick or multi-layered materials

- Heat-sensitive materials

- Complex shapes with tight tolerances

- Prototypes and low- to mid-volume runs

- Exotic or specialty metals and composites

Laser Cutting: Speed, Efficiency, and Integrated Forming

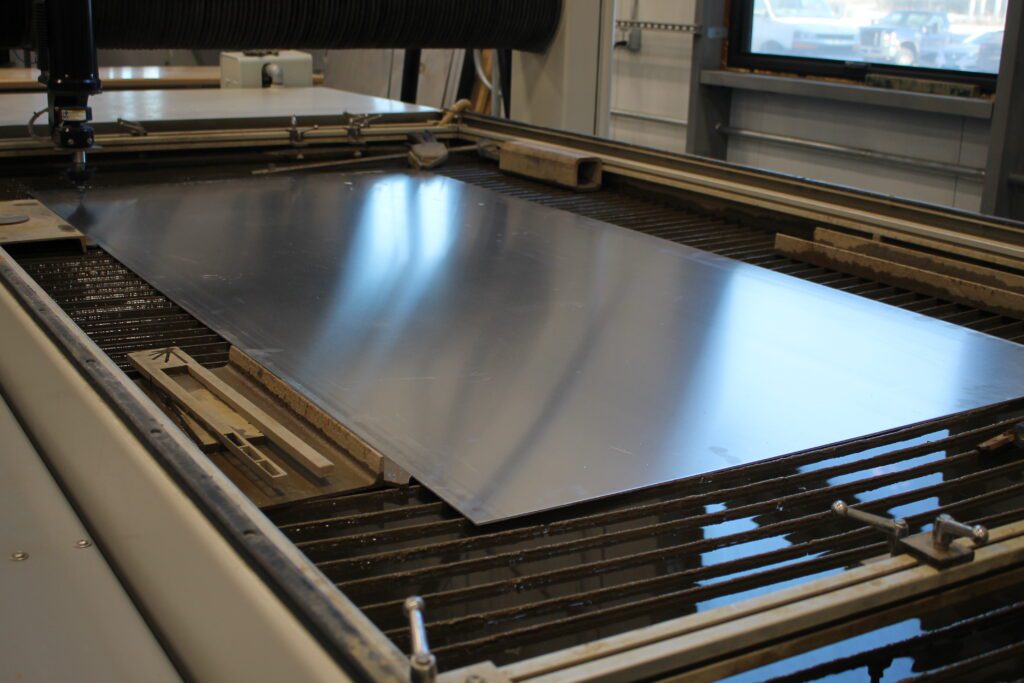

Laser cutting uses a focused beam of light to melt or vaporize material with high precision. At MSI, we utilize the Amada EML-2515 AJ Fiber Laser/Punch Combo — combining high-speed laser cutting with turret punching and forming in a fully integrated system.

Key Advantages of Fiber Laser Cutting with Punch Combo

- 3 kW AJ Fiber Laser Power: High-speed cutting of thin to moderately thick metals with clean edge quality.

- 33-Ton Servo Turret Punch Press: 55 turret stations with integrated tapping, countersinking, forming, and embossing — all in one machine setup.

- Exceptional Cutting Speeds: Extremely fast on thin-gauge metals (steel, stainless, aluminum, copper, brass) with minimal taper.

- Forming + Cutting in One Operation: The punch-laser combo eliminates secondary operations like forming, deburring, and tapping.

- Automation-Ready: Designed for high-volume, lights-out production with consistent repeatability.

- Max Sheet Size: Cuts sheet sizes up to 60″ × 120″ (5’ × 10’) to accommodate a broad range of part sizes.

When to Use Laser Cutting with Punch Combo

- Thin to medium thickness metals (up to .25” thick)

- High production volumes with repeatable parts

- Parts requiring formed features, tapping, or countersinking

- Jobs where speed, part consistency, and efficiency are priorities

- Sheet metal enclosures, brackets, panels, and structural components

Waterjet vs. Laser Cutting: Quick Comparison

|

WATERJET CUTTING |

LASER PUNCH COMBO CUTTING | |

|---|---|---|

|

Cutting Process |

High-pressure water + abrasive |

Fiber laser + mechanical punch |

|

Heat-Affected Zone |

None |

Minimal |

|

Materials |

Nearly any (metals, composites, plastics) |

Metals (steel, stainless, aluminum, copper, brass) |

|

Max Thickness |

Up to 12” |

Up to .25” |

|

Tolerances |

+/- 0.005” |

+/- 0.002” – 0.005” |

|

Speed on Thin Material |

Moderate |

Extremely fast |

|

Secondary Operations |

Minimal |

Integrated forming, tapping, and countersinking |

|

Ideal For |

Prototypes, exotic materials, thick parts |

High-volume sheet metal parts with forming |

Why MSI Invested in Both Technologies

By offering both waterjet and laser punch combo cutting, MSI can match each customer’s specific job requirements. Our engineers review every project to determine:

- The most efficient cutting method

- The best process for material yield

- Optimal speed, accuracy, and part cost

This flexibility allows us to handle everything from high-mix, low-volume prototype runs to full-scale production with forming and secondary operations built into the cutting process. We also support soft material cutting through our Eastman M9000 Static Cutting Table, allowing us to handle technical textiles, carbon fiber, thin films, and flexible substrates as part of our complete contract manufacturing capabilities.

Work With a Contract Manufacturer Who Matches Process to Project

The cutting technology you choose directly affects your project cost, lead time, and finished part quality. MSI’s vertically integrated precision cutting services help OEMs, industrial manufacturers, and defense contractors solve complex manufacturing challenges — efficiently and with confidence. Let’s discuss your next project, fill out the form below or explore our full cutting capabilities.